Recycle valuable items from household products especially gold, copper, aluminum, metal, electronic components, dc motors, hobby, sensors, neodymium magnet, Computers, Electrical, DIY, Do it Yourself, Gold Electroplating, Nickel Plating, Chemistry

Showing posts with label Soldering Technique. Show all posts

Showing posts with label Soldering Technique. Show all posts

Another way to desolder capacitor from motherboard

One of the way that i never thought of removing capacitor from motherboard is shown in this video. Just using solder iron to heat up the solder joint. Once the solder is melted then you can start slowly wiggle while pulling the capacitor from it's place. Cool trick

This is another way using solder paste and DIY solder pot. It works brilliantly

Another great one using heat gun, solder iron, and solder paste

This is another way using solder paste and DIY solder pot. It works brilliantly

Another great one using heat gun, solder iron, and solder paste

What you need to solder motherboard

Motherboard soldering require precision and heat to get the best result. The wrong tools could have failed the soldering process big time so this is recommendation

1. At least 60 wattage solder irong

2. 0.8mm solder coil

3. Solder flux remover to remove flux

Complete reference http://capacitorlab.com/replacing-motherboard-capacitors-howto/

1. At least 60 wattage solder irong

2. 0.8mm solder coil

3. Solder flux remover to remove flux

Complete reference http://capacitorlab.com/replacing-motherboard-capacitors-howto/

Soldering Iron Tip Cleaner

REFRESHING THE TIP WITH GOOT BS-2 SOLDERING IRON TIP CLEANER

1. Optimal tip temperature for refreshing it is from 300 to 360˚C.

2. Dip the hot tip into the tip refresher.

3. Apply solder to the tip. Then carefully clean it with a moist sponge.

4. If the tip is still unclean, repeat steps 2 and 3 above.

WARNING! Make sure you completely remove the tip cleaner from the tip before starting to solder PCBs. If the tip cleaner remains on the tip it may stick to the PCB and corrode components.

http://toolboom.com/en/Soldering-Iron-Tip-Cleaner-GOOT-BS-2.php

1. Optimal tip temperature for refreshing it is from 300 to 360˚C.

2. Dip the hot tip into the tip refresher.

3. Apply solder to the tip. Then carefully clean it with a moist sponge.

4. If the tip is still unclean, repeat steps 2 and 3 above.

WARNING! Make sure you completely remove the tip cleaner from the tip before starting to solder PCBs. If the tip cleaner remains on the tip it may stick to the PCB and corrode components.

http://toolboom.com/en/Soldering-Iron-Tip-Cleaner-GOOT-BS-2.php

Maintaining Solder Iron Tips Guide

Very simple and straight to the point guide how to maintain solder iron tips http://www.inlandcraft.com/uguides/tipfailure.htm

Cheaper alternative solder flux remover

Solder flux remover can be expensive, in this video using Isopropyl alcohol and acetone works as good. See it yourself

How to clean oxidized solder tips

After heating and cooling the solder tips will eventually starting to get black - where it coated by the layer of oxidation. This is especially happens to cheap soldering tips of course the expensive one is no difference after using them for long time.

Another great and simple video explains how to maintain the solder iron tips using flux and solder. Then keep a blob of solder on the iron tips when it is not in used.

Very good simple guide how to maintain and service oxidized solder by the famous solder equipment manufacturer Hakko. Effective and simple to follow

1. Clean using fine sand paper for excessive solder tip oxidation

2. Always tinned the solder tips when not in use

3. Use wet sponge

http://www.hakko.com/english/maintenance/topic_kotesaki.html.

http://www.hakko.com/english/products/hakko_ft700.html

http://www.hakko.com/english/maintenance/topic_oxidized.html

Why do we need to clean the oxidized solder tips? simply because oxidized tips will repel the solder and won't stick to the tips this will affect soldering process significantly. If the solder tips starting to get black you can try to use it the solder will melt away from the tips and won't stick at all.

In this video explains how to clean solder tips using sand paper. It's simple and effective.

Another great and simple video explains how to maintain the solder iron tips using flux and solder. Then keep a blob of solder on the iron tips when it is not in used.

Very good simple guide how to maintain and service oxidized solder by the famous solder equipment manufacturer Hakko. Effective and simple to follow

1. Clean using fine sand paper for excessive solder tip oxidation

2. Always tinned the solder tips when not in use

3. Use wet sponge

http://www.hakko.com/english/maintenance/topic_kotesaki.html.

http://www.hakko.com/english/products/hakko_ft700.html

http://www.hakko.com/english/maintenance/topic_oxidized.html

Soldering mistakes - tinning oxidized copper wire

This video explains why we should not tinning oxidized copper wire, as it will result in poor results. The solution is to use sand paper to remove scratch out the oxidized layer of the copper wire or cut from the new coating. This video explains the best

Simple basic soldering technique

Very nice simple video for beginners. The basic of soldering

Professional basic soldering lesson from Pace world. This is the most informative and precise lesson of soldering technique apply for professional industrial use

Professional basic soldering lesson from Pace world. This is the most informative and precise lesson of soldering technique apply for professional industrial use

Wave soldering - Manufactured factory soldering technique

Some people might wonder how the factory soldering is done. Well it is call wave soldering and watch this ow it is done by the machine. Clean and easy soldering process going through the conveyor rail. Flux and solder is applied along the way when it moves on the rail - looks simple but not sure in reality

Isopropyl alcohol used to remove solder flux residue

Near pure Isopropyl alcohol is used to remove flux residue from the circuit board after soldering.

Best Desoldering Technique

The best desoldering technique is using the solder wick for tiny electronic components or use hot air gun for larger components. De-soldering pump is much more difficult and ineffective sometimes

Another way to quickly desolder electronic component is using the solder pot

Magical: Chipquik is another liquid solution that can be used for desoldering process. What it does is to liquidify the solder in approximately 10 seconds. - then you can remove it easily

This video explains some tips of the best desoldering technique using the Hakko 808 desoldering gun and also the heat gun. If want to work on professional repairing for the electronic board the Hakko 808 simply do the best job not only it is effective but also minimize damage to the circuit board. Heat gun is another good method but the heat can sometimes too much.

Very good video explains how to use desoldering wick to remove solder effectively. Always use fresh wick because old wick maybe already oxidized. However you can still use the wick by sand paper them once it is very fine and shiny you can start using it to remove solder

Another way to quickly desolder electronic component is using the solder pot

Magical: Chipquik is another liquid solution that can be used for desoldering process. What it does is to liquidify the solder in approximately 10 seconds. - then you can remove it easily

This video explains some tips of the best desoldering technique using the Hakko 808 desoldering gun and also the heat gun. If want to work on professional repairing for the electronic board the Hakko 808 simply do the best job not only it is effective but also minimize damage to the circuit board. Heat gun is another good method but the heat can sometimes too much.

Very good video explains how to use desoldering wick to remove solder effectively. Always use fresh wick because old wick maybe already oxidized. However you can still use the wick by sand paper them once it is very fine and shiny you can start using it to remove solder

Best Soldering Technique

One of the most effective ways how to solder small and medium size electronic parts with neat and perfect outcome.

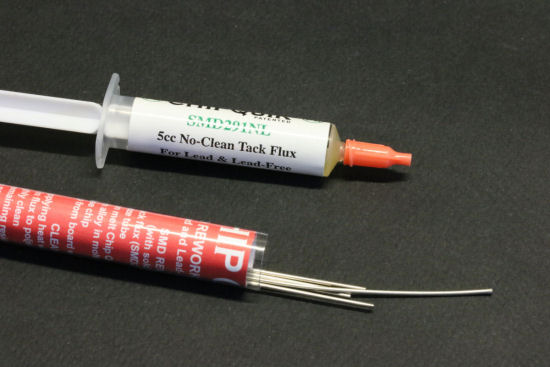

What you need

1. Good soldering iron at least 40w to 60w

2. Solder paste (with flux)

3. Solder flux

4. Sponge or brass to clean solder tips

5. Heat / hot air gun solder

6. 99.99% Alcohol to clean the flux (finishing)

What you need

1. Good soldering iron at least 40w to 60w

2. Solder paste (with flux)

3. Solder flux

4. Sponge or brass to clean solder tips

5. Heat / hot air gun solder

6. 99.99% Alcohol to clean the flux (finishing)

Subscribe to:

Posts (Atom)